Metal guillotine knives: Stulle Mark

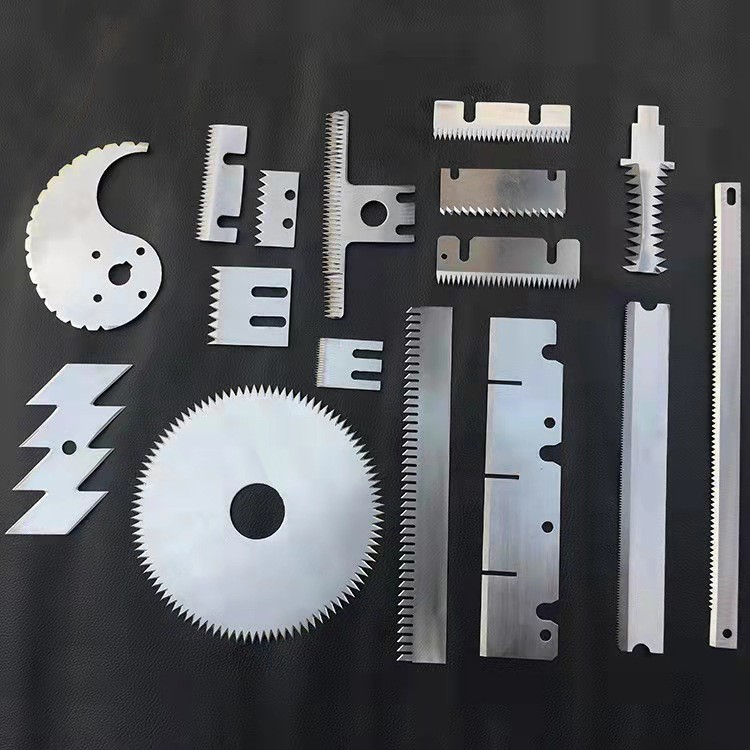

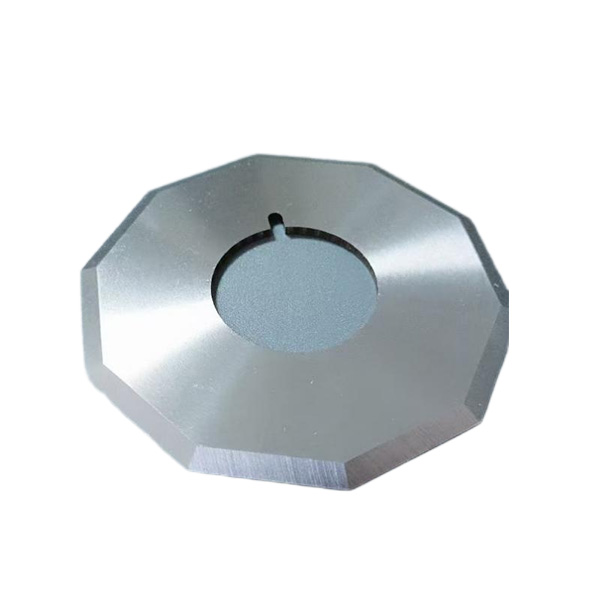

Guillotin knives are not just pieces of metal. These are tools that perform thin and complex work on cutting metals, starting from the thin sheet to strong steels. When choosing a knife, you need to understand that its quality directly affects the accuracy of the cut, the durability of the tool and the safety of work. One of the key characteristics is the brand of steel, which determines the strength, wear resistance and other important properties.

The choice of steel brand: not only numbers

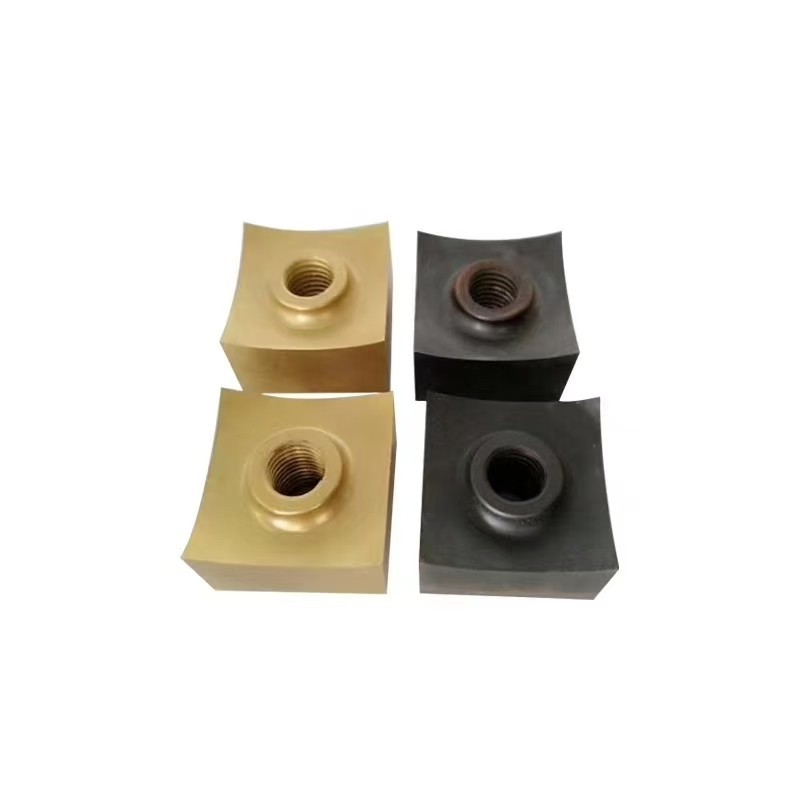

Different brands of steels have different properties. High strength and wear resistance - sounds good, but there are specific characteristics behind this. For example, steel with a high carbon content, as a rule, is very durable, but can break with too large loads. For cutting thin sheets, you need other steel, more plastic and less prone to cracking. Factors such as corrosion resistance and the possibility of hardening gives the necessary properties are also taken into account. Simply put, the choice depends on which metal and to what volume you plan to cut.

Practical experience in the selection of knives

If you work professionally with metal, then experienced specialists can give you valuable tips. Consult your colleagues, study reviews about different manufacturers. Ultimately, the choice of steel brand is a matter of balance between price, quality and capabilities. Look for trusted suppliers. Do not save on knives if you want to maintain the quality and accuracy of work.

The influence of the brand steel on the life

A good brand of steel, properly made and educated, will provide a knife for guillotin for a long service life. A knife made of high -quality steel will last longer, provide a pure cut without deformations and will avoid expensive breakdowns. This means less replacement costs and more time for work. The choice of the right steel brand is an investment in the long -term quality of your guillotine.