Plastmass crusher knives

Plastics surround us everywhere - from toys to household appliances. But what happens to plastic products that have served their term? Correctly processing them is an important task, and this requires specialized tools, in particular, knives for a crusher. Imagine a huge car that is dealing with plastic garbage, turning it into tiny pieces, ready for further processing. The knives in this machine are a key element of the entire process.

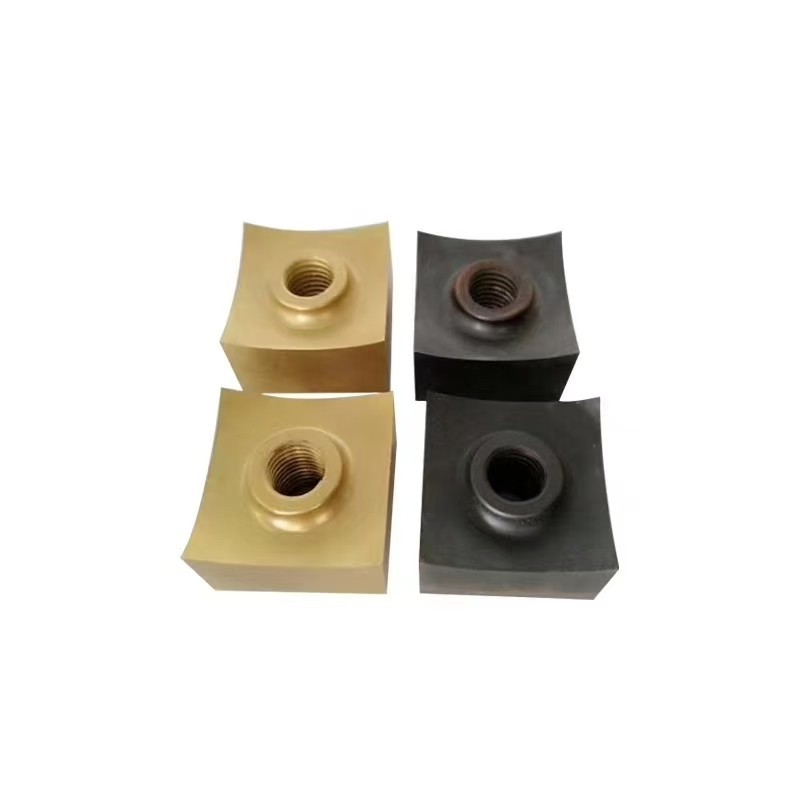

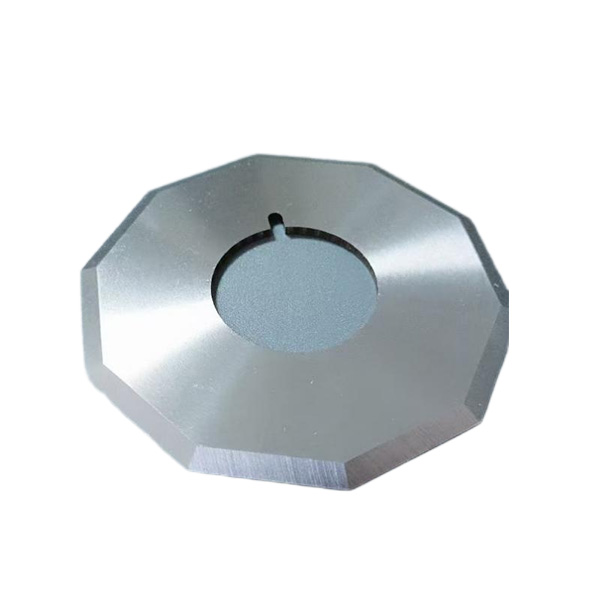

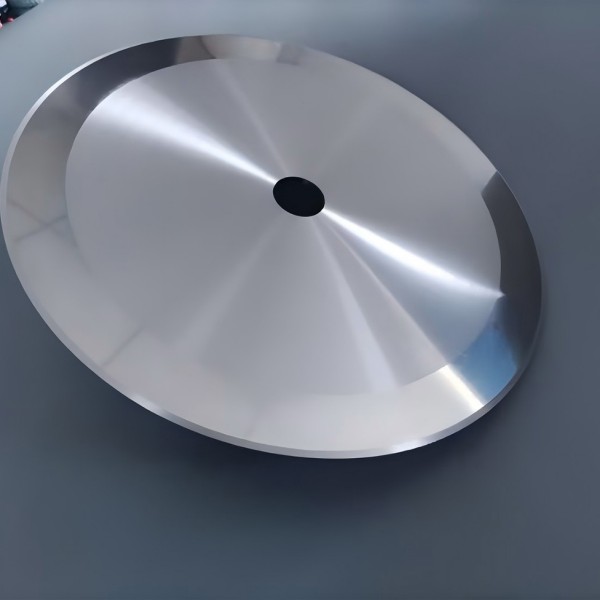

Types of knives and their role

Different types of plastic require different knives. Knives can be made of various alloys, with different geometry of the blade. Some knives are sharpened for cutting soft, others for hard materials. The effectiveness of the entire crusher directly depends on the quality and severity of the knife. Dumb knives will not only reduce performance, but can also damage the car itself, which will lead to breakdowns and additional costs. It is important to choose knives that are suitable for your type of plastic and the characteristics of the crusher.

Maintaining knife sharpness: pledged long -term work

Like any cutting equipment, the crusher knives will dull over time. This reduces productivity and increases the load on the mechanism. Regular sharpening or replacing knives is the key to their long service. Imagine that you use a dumb knife for cutting products - this is long and ineffective. In the same way, stupid knives in the crusher will not be able to effectively chop the plastic. Regular verification of severity and timely replacement of knives not only extends the service life of the equipment, but also allow you to maintain high quality plastic processing.

Choosing knives for a crusher: what to look for

When choosing knives for a crusher, you should pay attention to several important points. The first is the compatibility of knives with your crusher model. Different manufacturers and models have their specific requirements for the size and characteristics of knives. The second is the material of the manufacture of knives. Choose knives made of strong and wear -resistant alloys that can withstand high loads. And the third is the price. Of course, it is important to consider the cost, but you should not save on quality, as this can lead to higher costs in the future, due to the repair or breakdowns of the crusher. Knives of different price range are presented on the market, and the choice depends on your specific needs and financial capabilities.