Manufacturing knives for crushers

Range knives are an important detail in the work of many production, from grain processing to crushing rocks. They are not just pieces of metal; Is this? teeth? Machines that determine how effective and safe the process of crushing will occur. Properly manufactured knives are the key to uninterrupted operation and high performance of all equipment. Let's look at how these working tools are created.

The choice of material is the basis of strength

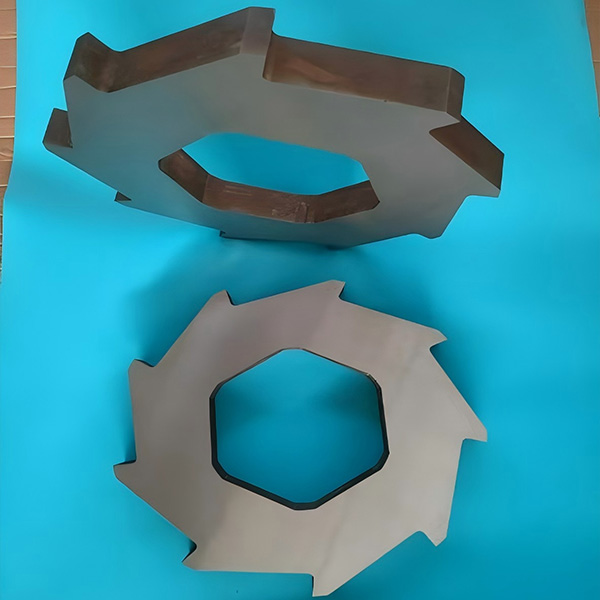

For the manufacture of knives, high -strength steels are used. This is not just an ordinary metal. These steel have high wear resistance, the ability to withstand huge loads and repeated blows. The special composition of the alloy, in particular, the percentage of carbon, determines how long the knife can withstand wear. It is impossible to underestimate thermal treatment, which gives the material the necessary strength and elasticity, allowing the knife not to break under load. The choice of the right alloy is already half the success.

Production process - accuracy and experience

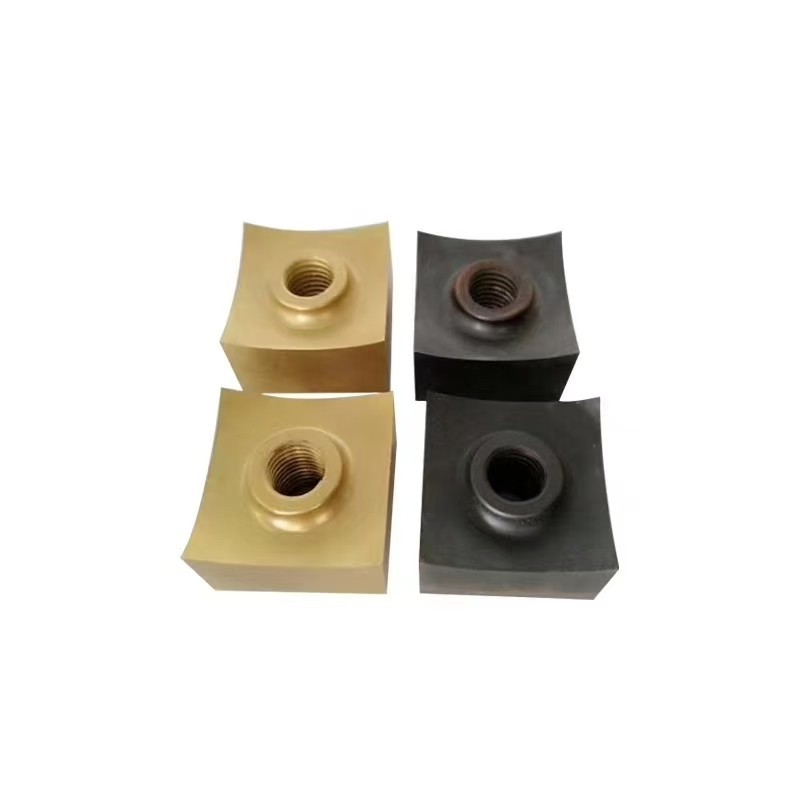

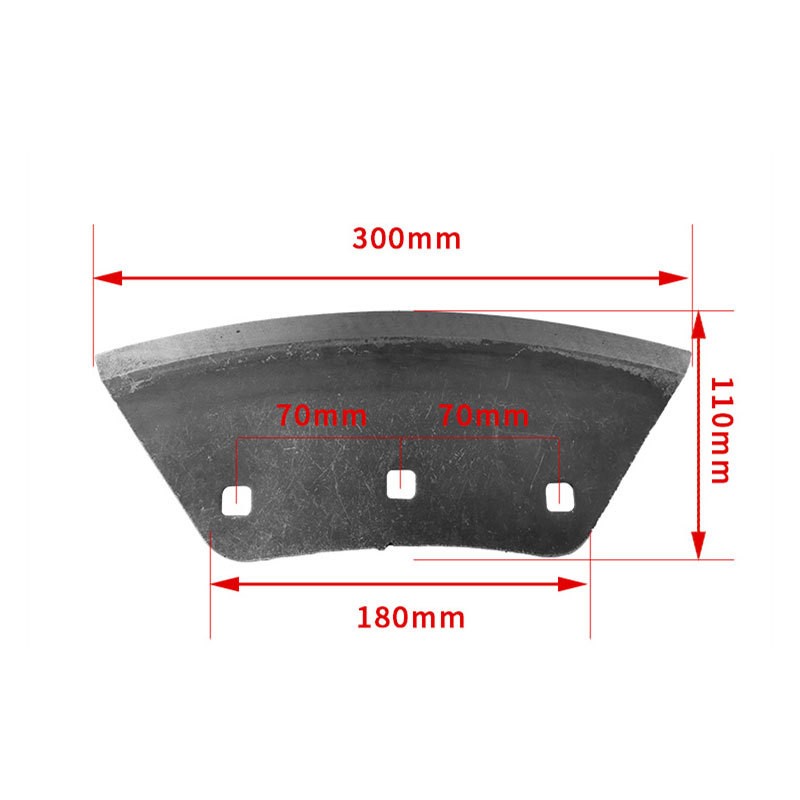

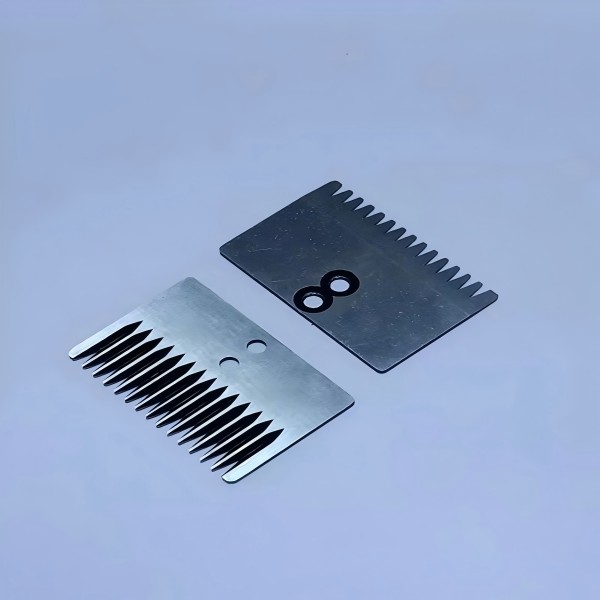

Making knives is not just welding or cutting. The process includes complex stages: from the exact calculation of the thickness and geometry of blades to sharpening and quality control. Metallurgists and technologists should perfectly calculate the structure so that the knife effectively fractions the material without exposing excessive loads. Each specific task of the crusher needs its own parameters of knives: thickness, shape, angle of sharpening, strength. All technology depends on the type of material processed and expected working conditions. Having different types of materials and conditions, engineers select knives that are as effective as possible. A huge role is played by the accuracy of the manufacture of each element.

Quality control - security security and durability

Quality testing is an integral part of the process. After each stage of manufacture, the knives are thoroughly tested for strength, geometric accuracy and resistance to wear. Special devices and professional skills of specialists help to ensure the exact size and shape of the blades, which guarantees the safety of the crushing installation. High -quality control is not only a guarantee of the durability of knives, but also the prevention of possible injuries and accidents in production. Only reliable, proven knives will be able to serve for a long time without leaving the system. This saves not only time, but also prevents large production problems.